Stainless Steel: Properties, Applications & Innovations

Table of Contents

- An Essential Material in Our Daily Lives

- Some Facts About Stainless Steel

- The Chemical Process: A Unique Combination of Elements

- Differences in Stainless Steel Types

- Applications and Importance

- Innovations and Future Outlook

- Conclusion

An Essential Material in Our Daily Lives

Stainless steel, also known as inox steel, is a metallic alloy primarily composed of iron and chromium (at least 10.5%), and often other elements such as nickel, molybdenum, and carbon. This unique material owes its popularity to its incredible resistance to corrosion, making it a preferred choice for a multitude of industrial and domestic applications. The combination of different chemical elements gives this alloy exceptional properties such as extended lifespan, high mechanical strength, and excellent recyclability.

Stainless steel was developed in the early 20th century, with the first significant production in 1913 by Harry Brearley, a British metallurgist. His discovery is often described as revolutionary because it solved persistent corrosion problems in critical industrial environments. Since then, stainless steel has continuously evolved, with constant innovations in its chemical compositions and production methods to meet the changing needs of global industry.

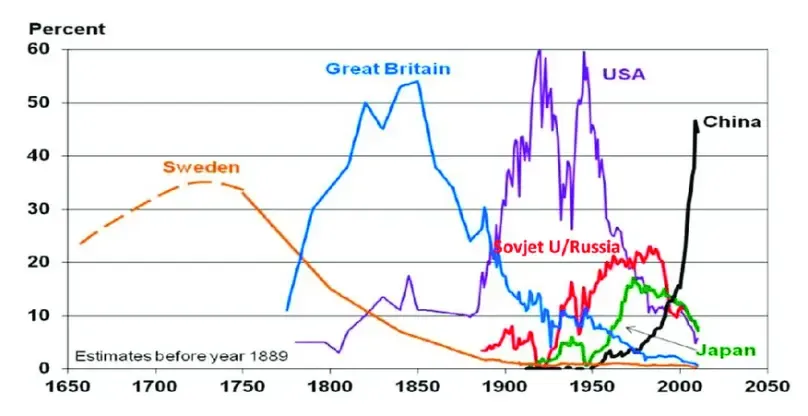

Today, India, China, and the European Union are among the world’s largest producers of stainless steel, with China accounting for more than 50% of global production in 2023. China’s leadership is due to abundant access to raw materials, a well-developed industrial infrastructure, and massive domestic demand in sectors such as construction, transportation, and high technology. In India, the stainless steel sector is growing rapidly, supported by government and private investments aimed at modernizing production facilities and increasing national capacity.

The importance of stainless steel in the global economy is significant. Studies show that the stainless steel industry directly or indirectly employs millions of people. China alone has more than 2,000 factories involved in the production and processing of stainless steel. International trade of this essential material also represents a significant share of exchanges in the industrial, medical, and technological sectors. For example, in 2022, stainless steel exports generated revenues of several tens of billions of dollars, reflecting the importance of this material in the global economy.

Some Facts About Stainless Steel

- Constantly Increasing Production: In 2022, global stainless steel production reached approximately 58 million tons, a 5% increase compared to the previous year. This growth is mainly driven by rising demand in the construction, automotive, and renewable energy sectors.

- 100% Recyclability: Stainless steel is one of the most recycled materials in the world. About 80% of stainless steel products are recycled at the end of their useful life. Stainless steel scrap is a valuable resource for reducing the industry's overall carbon footprint.

- Impressive Lifespan: Stainless steel products can last for several decades, even in demanding environments such as the marine industry. A famous example is the Chrysler Building in New York, whose stainless steel spire has remained intact for over 90 years.

The Chemical Process: A Unique Combination of Elements

The main property of stainless steel, its resistance to corrosion, comes from the formation of a thin passive chromium oxide layer on its surface. This layer, which regenerates naturally in the presence of oxygen, prevents corrosive elements like water and air from penetrating the metal structure.

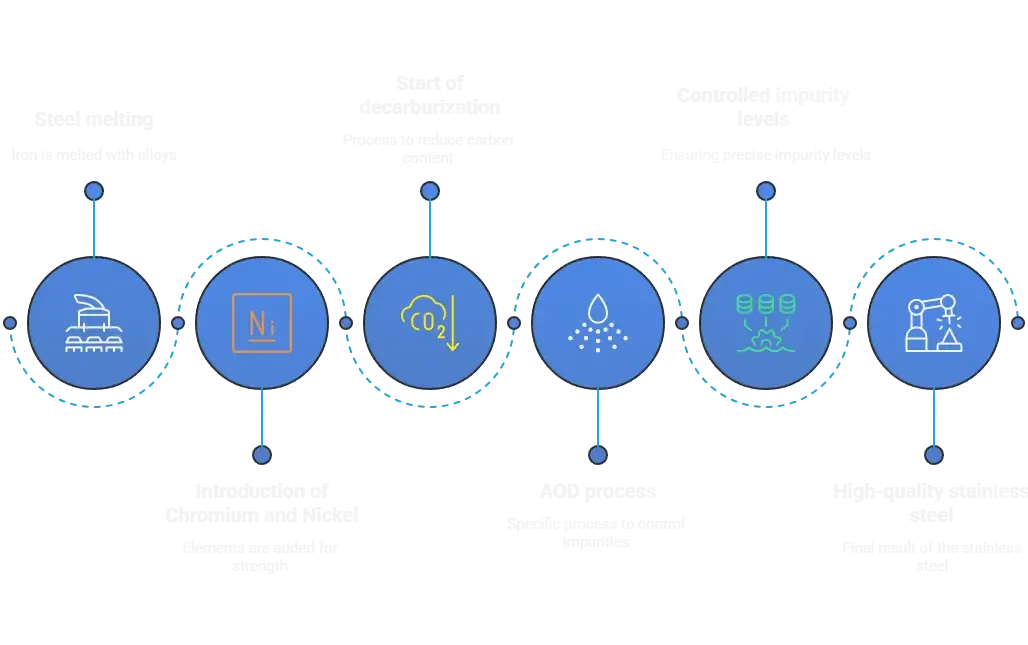

- Melting and Alloying: Iron is melted in a high-temperature furnace (1,600 to 1,700°C) with chromium and other elements such as nickel or molybdenum. Chromium plays a key role in enhancing corrosion resistance, while nickel improves ductility and malleability.

- Decarburization: This process reduces the carbon content to avoid the formation of carbides that could compromise corrosion resistance. Advanced technologies, such as the AOD (Argon-Oxygen Decarburization) process, allow precise control over impurity levels.

- Cooling and Forming: Once the alloy is created, the steel is cooled and then rolled into its final shapes (sheets, tubes, bars). These steps are critical for determining the mechanical properties of the final product.

- Surface Treatment: Finally, the stainless steel is polished or treated to enhance its appearance and performance. Techniques such as chemical pickling or electro-polishing are frequently used.

Differences in Stainless Steel Types

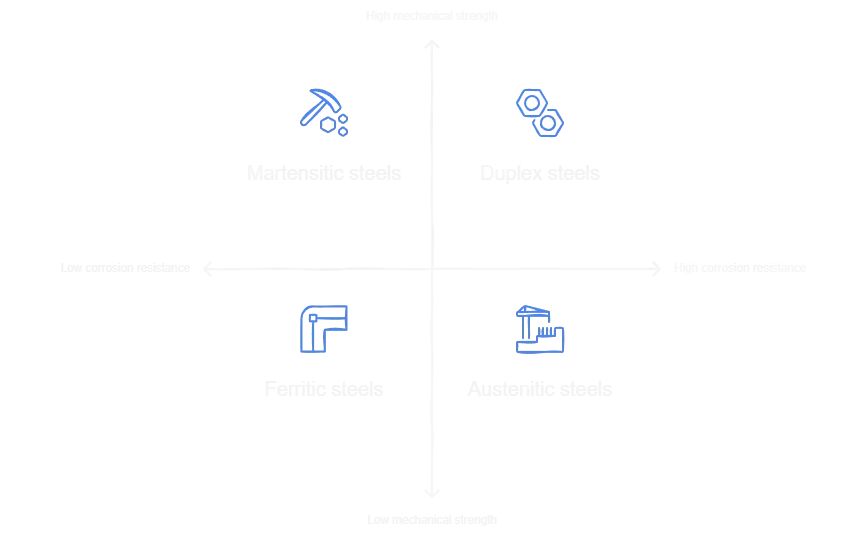

Stainless steel is divided into several families, each suited to specific needs:

- Austenitic Steels: Containing nickel, they are corrosion-resistant and very malleable. They make up about 70% of global production.

- Ferritic Steels: Less expensive due to low nickel content, they offer good corrosion resistance but are less ductile.

- Martensitic Steels: Known for their hardness and mechanical strength, they are commonly used for cutting tools.

- Duplex Steels: A mix of austenitic and ferritic steels, they combine high mechanical strength with excellent corrosion resistance.

Applications and Importance

Stainless steel is omnipresent in our daily lives and is used in a wide range of sectors:

- Medical: Surgical instruments, orthopedic implants, and imaging equipment. Its sterilizability and biocompatibility make it an essential choice.

- Culinary: Kitchen utensils, countertops, and appliances. Stainless steel is non-reactive with food and easy to clean.

- Construction: Building façades, bridges, and sculptures. Stainless steel is often used for its modern aesthetics and durability against weathering.

- Heavy Industry: Used in refineries, power plants, and marine infrastructure, stainless steel can withstand extreme environments without compromising strength.

- Transportation: Trains, airplanes, and cars incorporate stainless steel components for their lightness and extended lifespan.

Innovations and Future Outlook

With the rise of renewable energy, stainless steel plays a central role in the manufacturing of wind turbines, solar panels, and energy storage systems. Additionally, researchers are developing even more advanced alloys capable of withstanding extreme conditions such as very high temperatures or highly corrosive environments.

Conclusion

Stainless steel embodies the perfect balance between aesthetics, durability, and performance. As a modern and eco-friendly material, it will continue to play a key role in tomorrow’s technological and industrial innovations. Whether for a monumental bridge or a simple spoon, stainless steel is the discreet yet essential ally of our daily lives. With its countless applications and positive environmental impact thanks to its recyclability, it is ready to meet the challenges of the future.